E1216: RF Power could not maintain requested power

Issue

Plasma went out due to Error E1216: RF Power could not maintain requested power.

Environment

- iCAP 6000 series

- iCAP 7000 series

Resolution

Is the RF power matching up to the setpoint after the plasma is igniting? Is it making it through the spectrometer optimization? If yes, then proceed to troubleshooting tips below. If not then a hardware component could be the issue and you may need onsite service to resolve.

For example, in this picture the RF power readback (on left) is matching up with the setting on the right.

In this picture, the RF power readback is not matching up with the setpoint and instead is reading a value ~50W lower. In this example, the plasma went out during the spectrometer optimization and the E1216 error was displayed.

If the RF power matches up to the setpoint and instead the plasma is going out while the instrument is warming up or during the course of a run then the error may be caused by something affecting the conditions in the plasma in such a way that the RF Gen is constantly having to tune and not necessarily an issue with any actual RF hardware.

Please check the following in order to troubleshoot this issue:

1) Check the Argon Pressure – The incoming Argon pressure should be set to 85psi and should not be fluctuating from this setpoint

2) Check the Exhaust Flow – The exhaust flow should be set to 10 m/s for a Duo instrument and 5 m/s for a Radial instrument and should not be fluctuating more than +/- 0.5 m/s from this setpoint.

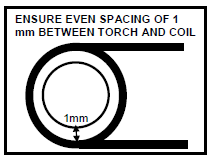

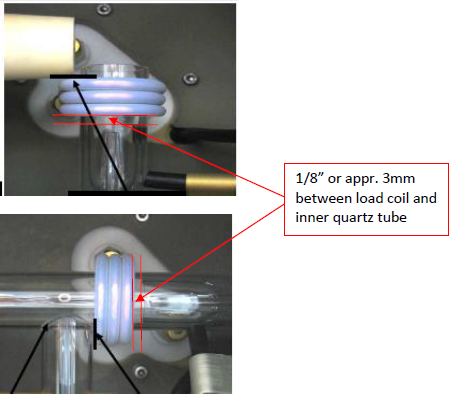

3) Check the load coil alignment:

a) Run a 1mm Allen wrench or wooden Q-tip around the space between the coil and outer quartz tube and see if resistance is encountered anywhere. If it is, suspect that the coil is touching the torch in that area. Gently bend the coil in a manner so that the coil is no longer touching the torch and re-check spacing.

b) The distance between the load coil and the inner quartz tube should be 1/8” or appr. 3mm. If it is not, gently bend the coil so that this distance is achieved.

4) Is there an air leak in the neb gas line from the gas box to the nebulizer? - This can be checked by snooping the fittings on either side of the line and also slightly bending the tubing to make sure it is still flexible and that there are no cracks in it.

5) Is there a leak in the channel in which the nebulizer is inserted into the spray chamber? -When you try to remove the nebulizer from the spray chamber there should be some resistance in doing so. If there is not, it is possible that the spray chamber o-rings are worn and need to be replaced.

6) Replace the nebulizer - The nebulizer may be operating inefficiently. When this happens the spray pattern can look normal. The only way to truly test this is to install a new nebulizer in.

Cause

If the actual RF power is out of range (+/- 20 W) for more than 20 seconds you will get error E1216