Hydrating a Dionex DRS 600, ERS 500e, or AERS 500 Carbonate Suppressor

Issue

During long term storage or shipment the suppressor can dry out which significantly impacts its performance. To avoid damage to the suppressor it is critical that it is hydrated before use which ensures the ion exchange materials are expanded for proper operation. This purpose of this article is to detail how to properly hydrate the suppressor.

Environment

-

DRS 600

-

ERS 500e

-

AERS 500 Carbonate Suppressor

-

Suppressor

Parts Recommended

| Part Number | Picture | Description |

| 014157 |  |

Clear 1.58 mm (0.062-in) ID PTFE TUBING,.062X.125 TFE |

| 048949 |  |

Flangeless ferrule |

| 052267 |  |

1/8 in. fittings FTG,NUT,FLNGLS,1/4-28X1/8 PK,RoHS |

| 042627 |  |

10-32 coupler FTG,CPLR,10-32FX10-32F,.02" |

| 042806 |  |

FTG,CPLR,1/4-28FX10-32,.02" |

Procedure

- Please read this guide completely before beginning the hydration procedure. We also recommend utilizing the full Suppressor Installation Checklist for suppressors which is attached to this article.

- If the suppressor being replaced is suspected to have failed due to a different component(s) in the flow path, please follow the troubleshooting guide in the attached Suppressor Installation Checklist.

- Mount the suppressor on the IC. Please see your specific instrument’s Dionex IC System Operator’s Manual for further details.

WARNING: Do not plug the suppressor cable into the system yet.

- Remove the guard and analytical column from the flow path during the hydration procedure by coupling the inlet and outlet of column tubing using a 10-32 coupler (P/N: 042627), as seen in Figure 1.

Figure 1. Coupling of inlet and outlet of the column via coupler.

- Turn on the pump to the application flow rate and flush the system with ultrapure water or ≤10 mM of eluent with the suppressor disconnected to check the overall system pressure. It should be ≤300 psi. If this is higher, follow the troubleshooting guide described in the Installation Checklist for suppressors. Allow the system to flush out for 10 minutes.

- Connect the water/eluent source to the “Eluent In” of the suppressor.

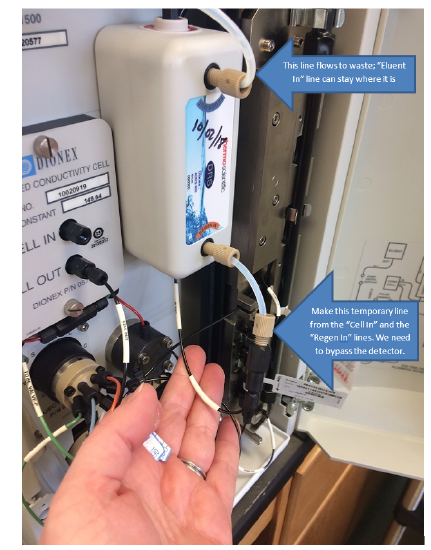

- Connect the “Eluent Out” port of the suppressor to the “Regen In” port of the suppressor using a short piece of tubing, bypassing the detector cell, as seen in Figure 2. The “Regen Out” goes to waste. Create the temporary line depicted in Figure 2, using the parts from the parts recommended list.

Figure 2. Suppressor connections for flushing.

- Slowly pump ≤10 mM of eluent or ultrapure water through the suppressor starting at 0.05 mL/min for a 2mm suppressor or 0.1 mL/min for a 4mm suppressor. Ramp the flow rate up to 0.125 mL/min or 0.5 mL/min, respectively.

- After reaching the final flow rate, allow the IC to flush the suppressor for 20 minutes. Record the backpressure of the system, should be ≤400 psi.

- After flushing, turn off the pump and allow the suppressor to rest for 20 minutes.

Additional Information

- Care should be taken not to exceed 100 psi of backpressure for 4mm or 150 psi of backpressure for 2mm on the suppressor. The backpressure to the suppressor includes any tubing, cell and backpressure coils that are connected to the eluent port of the suppressor. For specific instructions on how to check the backpressure, refer to Section 2.9.2 in the Operations Manual for Suppressor.

- It is highly recommended that the hydration protocols are accomplished using the IC system. Syringe-based methods are not recommended due to the backpressure of the eluent channel. This method will not completely displace the content of the eluent channel in a reproducible manner and will result in a slow startup time for the ion chromatograph.

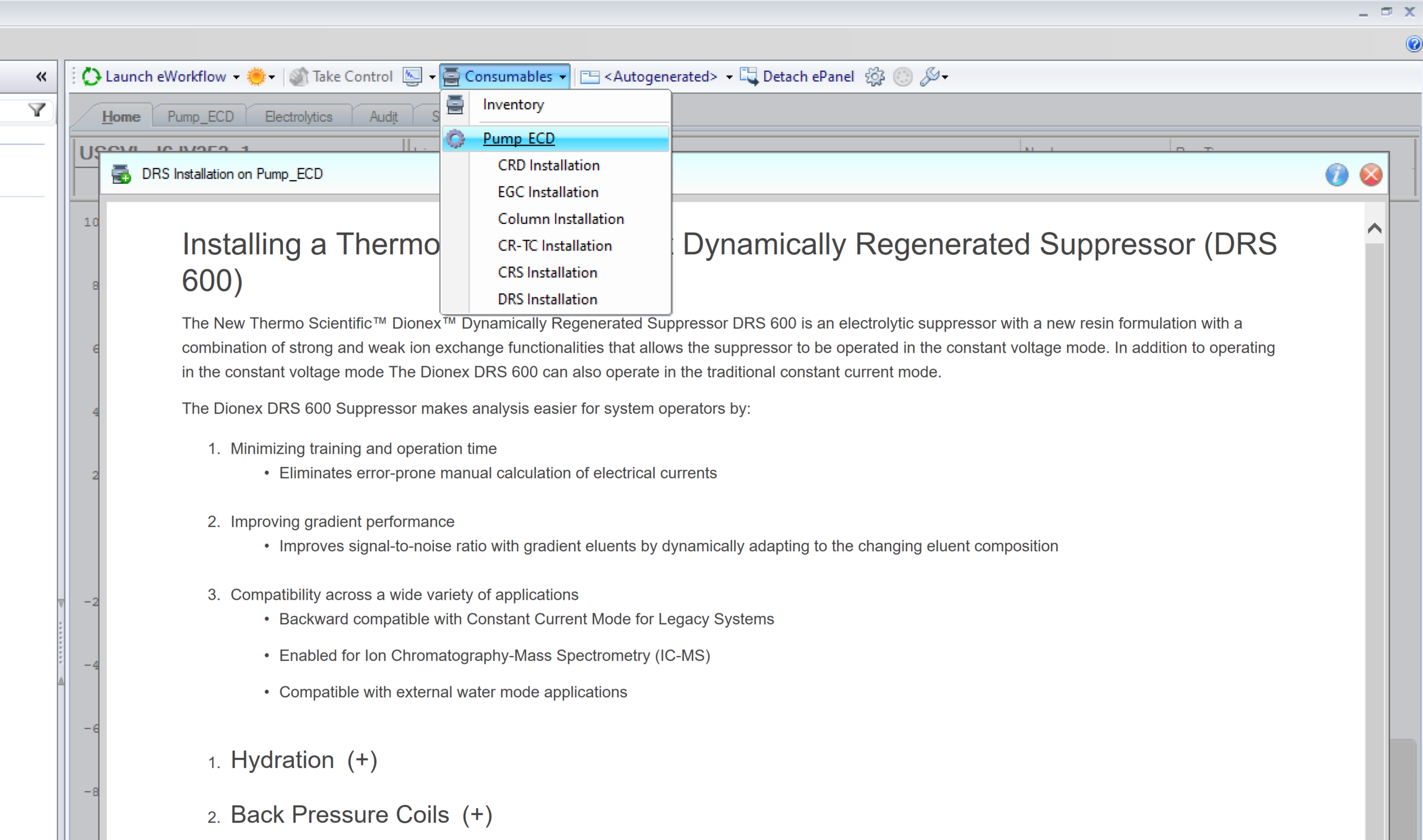

- Additional written instructions can be found in Chromeleon under Instrument -> Consumables illustrated in Figure 3.

Figure 3. Additional instructions for suppressor installation.

- Detailed video instructions on how to install suppressors can be found on the Thermo Fisher Chromatography & Mass Spectrometry Solutions Youtube channel:

Attachment(s)

| File | Last Modified |

|---|---|

| Suppressor_Installation_Checklist.pdf | May 25, 2022 |