Over Voltage Error

Issue

Over voltage error - Supressor

Environment

- Ion Chromatography

- AERS

- ADRS

- CERS

- Suppressors

Resolution

Test the system backpressure to ensure eluent is flowing freely through the suppressor:

- For 2mm ID suppressors, the pressure should not exceed 150 psi and for 4mm ID suppressors, the pressure should not exceed 100 psi:

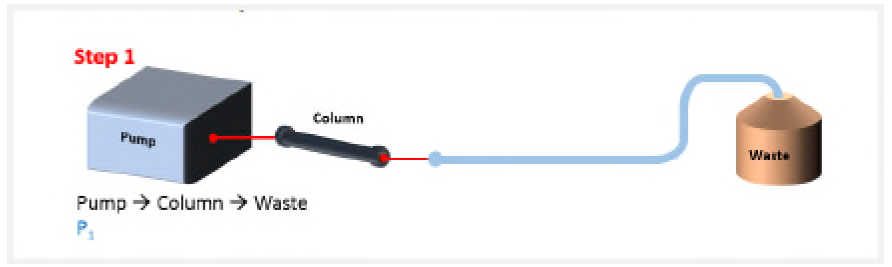

- Remove old suppressor, direct the column flow to waste, set column flow to normal flow rate and record system pressure (P1).

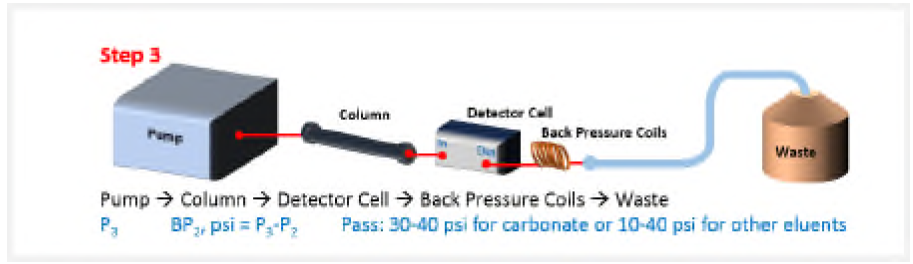

- Connect tubing from column directly to conductivity cell tubing with 10-32 union (p/n 042627 or 074083), leave back pressure coils installed, direct flow to waste, set column flow to normal flow rate and record system pressure (P2). The pressure difference from Step 1 and Step 2 should be < 50 psi. If pressure is high, test conductivity cell and back pressure coils separately – see troubleshooting.

- Remove old suppressor, direct the column flow to waste, set column flow to normal flow rate and record system pressure (P1).

Troubleshooting:

- Replace, adjust or add back pressure tubing to achieve proper back pressure – see below.

4 mm Chromatography 2 mm Chromatography P/N: 045877 P/N: 045878 1 Coil = 1.5 - 3.0 mL/min 1 Coil = 0.37 - 0.75 mL/min 2 Coil = 0.5 - 1.5 mL/min 2 Coil = 0.12 - 0.37 mL/min

Testing Suppressor and Re-Hydrating:

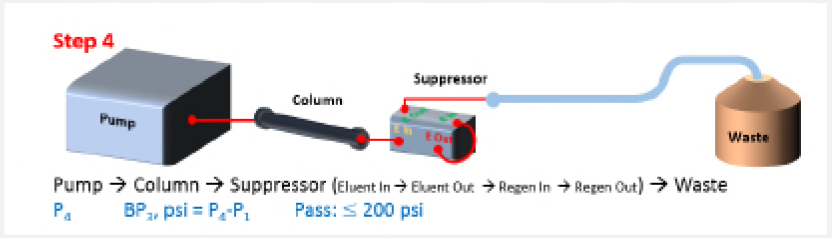

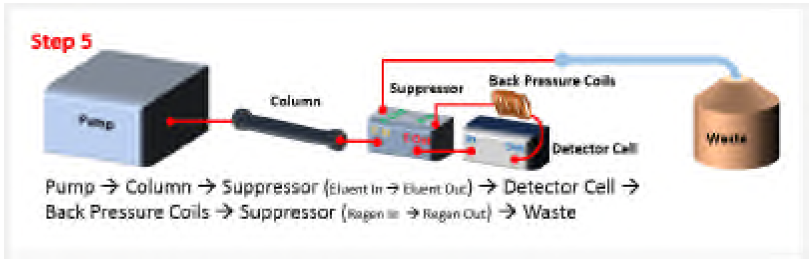

- Connect tubing from the column to the Suppressor’s Eluent In Port, connect tubing from Cell Out to the Suppressor’s Eluent Out Port, reinstall existing Regen Out and Regen In tubing to proper Suppressor Regent Ports. Do not apply any current to suppressor.

- Pump application eluent at 50% of normal flow rate for 5 minutes, stop pump for 20 minutes.

Restore:

- Restore to normal operating by including conductivity cell and back pressure tubing.

If the suppressor is still giving an over voltage error, contact Technical Support.

Attachment(s)

| File | Last Modified |

|---|---|

| over voltage - image 01.png | January 12, 2022 |

| over voltage - image 02.png | January 12, 2022 |

| over voltage - image 03.png | January 12, 2022 |

| over voltage - image 04.png | January 12, 2022 |