Maintenance Schedule for the Summit Spectrometer

Your Thermo Scientific Nicolet Summit FTIR Spectrometer requires little upkeep and no daily maintenance. However, basic care will ensure continued peak performance. Follow the guidelines in this article. For best performance, leave the spectrometer powered on.

|

Static electricity can permanently damage critical components in your spectrometer. To help prevent such damage, follow these recommendations:

|

Weekly Maintenance

Verify the Spectrometer Performance

The OMNIC Paradigm software includes qualification and performance verification (PV) workflows for your Summit spectrometer. The qualification workflows are standard industry-wide qualification tests you most likely recognize (for example, European Pharmacopoeia, Japanese Pharmacopoeia, etc.). The PV workflow runs a series of standard tests to verify instrument operation and ensure the accuracy of your data. Any required reference standards are supplied inside the instrument and controlled by the OMNIC Paradigm software.

We recommend that you run the PV workflow or your preferred qualification workflow at least once a week.

Clean the Spectrometer

The spectrometer and touchscreen can be cleaned only as recommended. See Clean the Spectrometer and Touchscreen.

Monthly Maintenance

Check the Humidity Indicator

The spectrometer’s optical components can be easily damaged by excessive moisture in the air. The spectrometer is sealed and its components are protected by two desiccant canisters that absorb moisture. Monitor the instrument humidity in OMNIC Paradigm software.

The spectrometer’s optical components can be easily damaged by excessive moisture in the air. The spectrometer is sealed and its components are protected by two desiccant canisters that absorb moisture. A humidity indicator located here monitors the humidity level inside the spectrometer.

You can also monitor the humidity through OMNIC Paradigm software. In the Desktop interface, click the instrument icon to view the system status, or in the Touchscreen interface, select the Diagnostics icon. The humidity level is listed in the Environment section.

Location of Humidity Indicator

Check the humidity indicator at least once a month and change the desiccant canisters when needed (see the table below), or purchase and install a purge kit. See "Install and Maintain a Purge Kit" for more information.

|

Humidity Indicator State |

Meaning |

Action |

|

Blue |

Desiccant is fully charged |

None |

|

Light blue |

Desiccant is becoming saturated with moisture and no longer providing sufficient protection |

Replace the desiccant |

|

Pink or white |

Desiccant has expired |

Replace the desiccant and the humidity indicator |

For more information, see "Replace the Desiccant".

|

We recommend that you keep the spectrometer sealed and desiccated, or sealed and purged with dry air or nitrogen, at all times. Equipment damage due to failure to maintain seal and desiccation and/or purge is not covered under the warranty. If you have questions about this requirement, please contact us. |

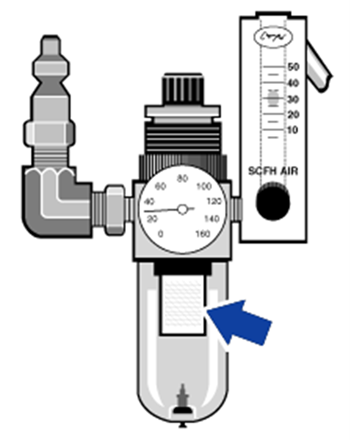

Check the Purge Gas Filter

If your spectrometer is purged with nitrogen or dry air, check the purge filter at least once a month.

Replace the filter when it is yellow, or otherwise discolored, or if it is contaminated with debris or foreign particles. For more information, see "Check and Change the Purge Gas Filter".

The purge filter is located inside of the plastic bowl below the pressure gauge.

Attachment(s):

| File | Last Modified |

|---|---|

| 110922_iS5 Purge Gas Filter.png | July 22, 2022 |

| 115333_Summit Humidity Indicator Location.jpg | July 22, 2022 |